07740 877 544

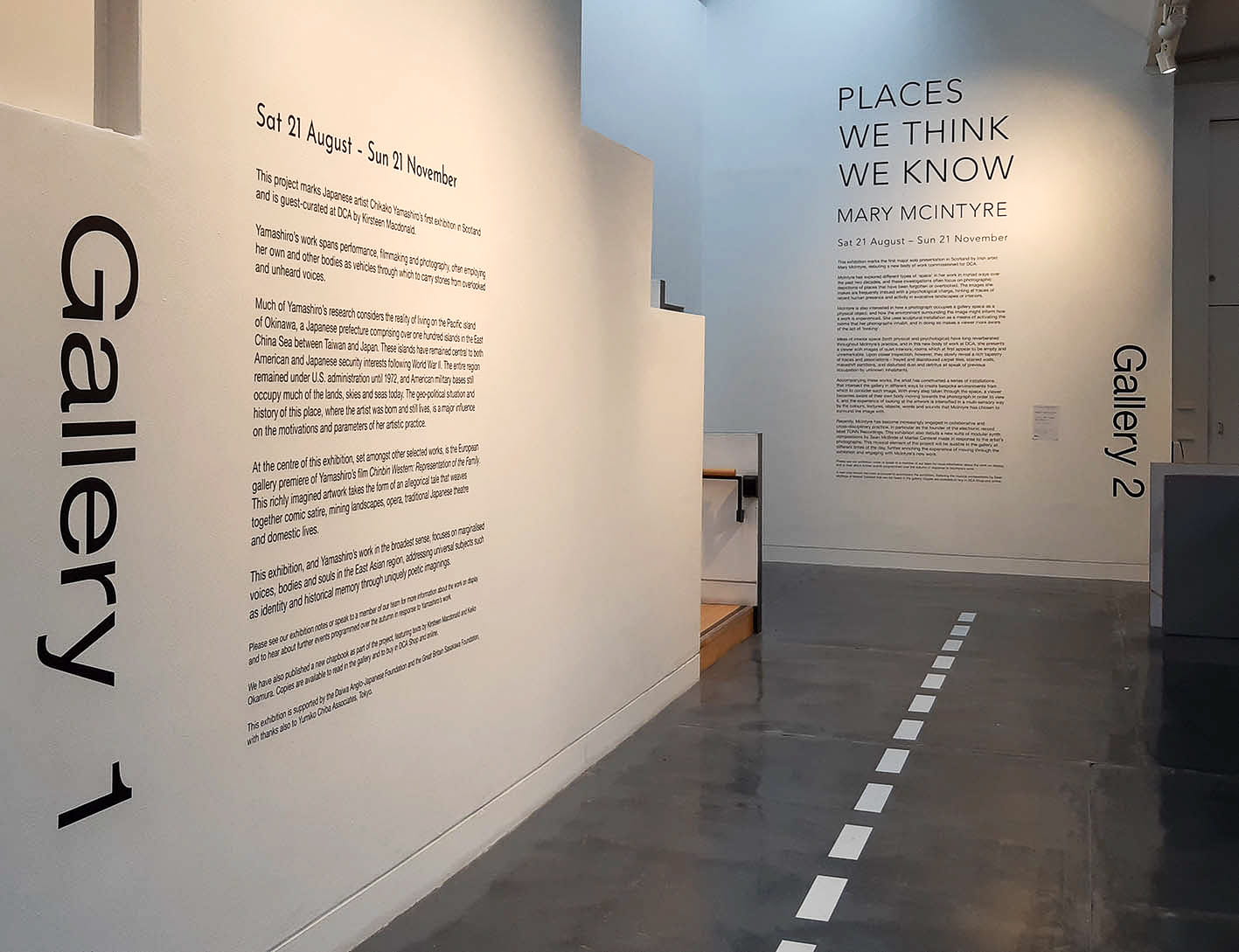

Vinyl lettering in Dundee Contemporary Arts

What is vinyl?

Signmaking vinyl is an adhesive backed, flexible plastic film. Available in an ever expanding range of colours, finishes, and applications. There are two types of vinyl films – calendered and cast. Each has differing properties.

Calendered vinyl is satisfactory for flat panel application. It’s generally stiffer and feels thicker than cast vinyl. It’s also more affordable than cast vinyl. I use calendered vinyl for the majority of general signage, such as flat signs and slightly contoured vehicle graphics.

Cast vinyl has a larger colour range, longer exterior lifespan, and wider range of uses. It’s designed to conform to uneven surfaces and is generally more advanced than calendered films. I use cast vinyl for demanding applications, such as moulding into vehicle panel recesses.

How signmaking vinyl is made

Both calendered and cast vinyl begin as mixed raw ingredients. These include chemicals such as PVC powder, liquidisers, and colour pigments.

The calendered vinyl ingredients are heated, kneaded, and squeezed through rollers to make the mixture thin. The mixture is passed through a long extrusion system which forms the original paste into rolls of flexible film.

The cast vinyl ingredients are poured in liquid form onto a casting sheet. The liquid settles into a very thin layer before being baked in a series of ovens. Cast vinyl is then wound up into rolls before the adhesive is applied to one side.

How vinyl lettering is made

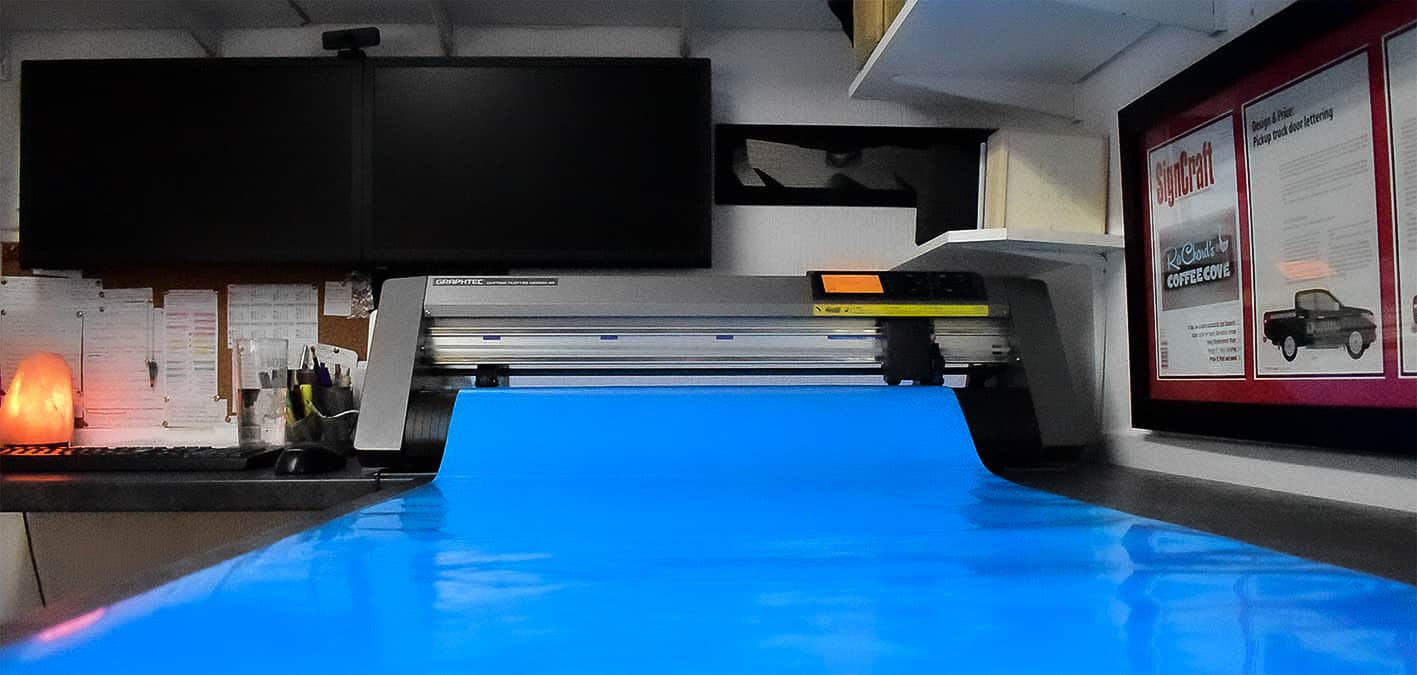

A plotter (or cutter) is a machine with a cutting blade. It’s connected to a computer which runs signmaking software. The software sends data to the plotter as geometric paths of outlined shapes.

The vinyl is clamped between rollers on the plotter. Rollers push and pull the vinyl whilst the cutting blade moves perpendicular to the vinyl fed rollers. In turn, the blade scribes the paths of shapes onto the roll of vinyl.

Once the data is complete cutting, the vinyl roll is removed from the plotter.

Excess vinyl is then removed from the scribed surface, leaving only the cut shapes (or lettering) on the vinyl backing (the liner). This process is called weeding which involves manual labour.

Vinyl handles differently from one grade to the next. As such, an intimate understanding of vinyl is necessary to weed lettering efficiently. Care and skill are vital when removing excess vinyl from small and ornate lettering.

Typefaces for vinyl lettering

Dependent on size, most solid stroke fonts can be cut from vinyl. I describe solid strokes as letterforms that do not possess irregular edges or speckled effects. Such fonts are too intricate and should be avoided for cutting small vinyl production.

Weeding involves the movement of cut vinyl. When scribed paths are too close together, removing excess vinyl agitates the neighbouring cut paths. Therefore, textured or grungy typefaces, as well as very thin stroke widths do not weed successfully from vinyl.

Sizes of vinyl lettering

A rule of thumb is to gauge the diameter of a lower case tittle (the dot of an ‘i’) or a punctuation mark, such as a full stop. No less than two millimetres diameter is recommended. The weight of the font will also affect the success of weeding.

Although vinyl lettering can be cut at sizes as low as three millimetres, weeding at this size is futile. The widths of letter strokes, as well as the style of typeface, are crucial when weeding vinyl lettering. Paragraphs of text smaller than ten millimetres capital height involve labour which may be unjustified for the cost of your project.

For example, an ornamental script will be difficult to weed at cap heights of five millimetres. This is due to the hairline thicknesses of the letter’s strokes.

Vinyl lettering for exhibitions

Exhibition titles, subheadings, and paragraphs of cap heights no less than ten millimetres are often cut in vinyl. Artwork should be provided as scaled vectors with specifications of colour, finish, and the application surface.

Size, weight, quantity, and finish are all factors that influence the method of lettering for exhibitions. As well as the surface to which the vinyl is to be applied.

Samples are available on request. I’m always happy to discuss alternative methods for producing exhibition lettering, which can’t be successfully produced in cut vinyl.

Surfaces which vinyl lettering can be applied to

Smooth surfaces are best for vinyl lettering to adequately bond.

Some paints and coatings can repel the vinyl’s adhesive, as well as textured surfaces. Sanding between coats of paints will minimise textures caused by the painting process and aid the adhesion of vinyl lettering.

In some circumstances, heat is applied to the vinyl to encourage the lettering to stick. The size and weight of the lettering also influence how well the vinyl adheres to the surface. Larger or thicker lettering has more adhesive to grab onto the surface, as opposed to thin or smaller stroke widths.

Applying vinyl lettering

Vinyl lettering is applied with transfer tape. The tape is usually low tack, similar to masking tape.

The transfer tape is applied to the face of the vinyl lettering and then peeled off of the liner. The transferred vinyl is then positioned on the surface before firm pressure is applied. Transfer tape is then carefully peeled off of the surface to leave the vinyl lettering in place.

The application process involves touching the surface. Easily marked paints and coatings should be avoided as backgrounds for vinyl lettering and graphics.

Learn how to do it by visiting here.

Colours and finishes

Unlike paints or inks which can be mixed to match specific colours, off-the-shelf vinyl is limited to colours that vinyl manufacturers provide. There is, however, a wide range of colours to choose from.

Gloss and matt colours are available. With the choice of matt vinyl colours, significantly less than gloss colours. However, matt laminates can be applied to gloss colours in some circumstances.

Alternatively, vinyl lettering can be printed to match a specific colour. Digitally printed vinyl is thicker than standard vinyl due to the laminate applied on top of the print. Cutting and weeding the thicker than standard vinyl has size limitations, especially for lettering smaller than twenty millimetres cap height.

Vinyl finishes and effects are constantly expanding. With woodgrain, metallics, iridescent, reflective, and etched effects to name only a few. Each has differing durability and use of application. Samples are available on request.

Durability

Cast vinyl lasts longer than calendered vinyl in exterior environments.

Interior applied cast vinyl lettering lasts indefinitely on smooth, sound surfaces away from direct UV rays. Often, short term (1-3 years) vinyl is used for interior application and performs well.

Manufacturers stipulate some of their products as up to ten years exterior lifespan. Cast vinyl lettering is most often used for the longer exterior term.

Digitally printed vinyl lettering will not retain its shape nor lustre as long as manufactured, self-coloured vinyl. This is due to the ink and the laminate being exposed to exterior conditions. However, digitally printed vinyl can last approximately three years before fading occurs. The lettering’s environment will affect the durability of printed vinyl, as well as the cleaning of the vinyl.

Greater durability equals higher costs and each project is evaluated for the appropriate choice of vinyl.

Removing vinyl lettering

Manufacturers market some of their products as short term and removable. Although there are films that don’t possess adhesives and truly are mess-free upon removal, most types of vinyl leave a gum residue behind.

The extent of gum residue left behind varies significantly. Exterior conditions such as temperatures and UV rays affect how the vinyl’s adhesive bonds to its surface. As well as the surface itself.

When safe to do so, heat should be used to ease the removal of the vinyl. Learn more about removing vinyl by visiting here. Scroll to the bottom of the page and download my guide.

For more information about vinyl graphics, visit here.

Need advice and a quote for your vinyl lettering in Dundee? Get in touch to find out more.